Looking great! Would you mind sharing the 3d files? Also, what program are you using to draft these in?

Ball Bearing Knex SS Train

#41

Posted 31 May 2019 - 05:30 PM

#42

Posted 03 June 2019 - 10:08 AM

Looking great! Would you mind sharing the 3d files? Also, what program are you using to draft these in?

Thanks, I'm currently using onshape to draft them which seems to be working quite well!

Unfortunately, I don't want to share the files quite yet. There is still some tweaking that needs to happen so if I was to share them, I want to make sure it is complete. I'm also just playing it safe right now and not sharing the files yet as I don't want someone (I'm thinking more or less non-SSC people...) to use the files and claim them as their own and/or use them for some sort of gain (profit, etc.) or something.

Once the files/models seem to be good, and if this becomes a popular upgrade for people, I'd be interested in sharing the file.

#43

Posted 03 June 2019 - 12:17 PM

The ball-bearing assembly train went from a starting height of 140 cm (55 inch) to a height of 117 cm (46 inch).

That is very impressive. I achieved about the same ratio with a heavily weighted train of 7 coaches, so it would be interesting to see how these behave when you add some weight to them.

#44

Posted 04 June 2019 - 08:05 AM

How long does it take to make an assembly for one middle or back car? (6 wheels total, 3 on each side) I ask this because I'm wondering if installing the ball bearings requires surgeon-like steady hands. (If it does, then I'll assume that the VV version of this would require God-level-surgeon-like steady hands.)

#45

Posted 04 June 2019 - 12:09 PM

How long does it take to make an assembly for one middle or back car? (6 wheels total, 3 on each side) I ask this because I'm wondering if installing the ball bearings requires surgeon-like steady hands. (If it does, then I'll assume that the VV version of this would require God-level-surgeon-like steady hands.)

I think I understand what you're asking/saying, so.....

You don't need steady hands, but you do need some time. Each assembly takes a hour to print (fine extrusion setting) and some time to tap/thread the holes where the screws go through. Prepping the car for the assemblies also takes a little time as you have to slightly widen two holes and cut off some small pieces from the train.

Once everything is set up (which is probably more what you are referring to) it takes around 10 minutes to install all the screws and bearings onto the assemblies and onto the train.

Mmh, wonder if making a vv version should be a thing. Do many people here make coasters with the VV sets? Maybe this is something to think about......

#46

Posted 04 June 2019 - 12:17 PM

I would definitely love to see what you could come up with for vv but I realllllly would like to see the finished SS finished as soon as possible.

I'm getting antsy to build again in a big way.

- JohnnyR24 likes this

Every post is a love letter to a forum once full of innovation

#47

Posted 04 June 2019 - 01:38 PM

I'm curious how you centered the bearing on a smaller diameter machine screw. I assume you have a 3D printed piece to insert into the bearing itself (OD 5mm and an ID of whatever the screw size is)? It looks like you have a similar setup for the "standoffs" that have an OD of slightly greater than 5mm. Am I on the right track here? Is there more going on with how those bearings are mounted? Some detailed pics of it partially disassembled would be awesome! Sizes of the machine screws used would be awesome too (honestly a full hardware parts list would be amazing).

Also, how on earth are you tapping these 3D parts, lol? Just using the machine screw and doing it by hand carefully, or do you have a more professional setup?

Thanks for all the info!

#48

Posted 05 June 2019 - 06:50 AM

I'm curious how you centered the bearing on a smaller diameter machine screw. I assume you have a 3D printed piece to insert into the bearing itself (OD 5mm and an ID of whatever the screw size is)? It looks like you have a similar setup for the "standoffs" that have an OD of slightly greater than 5mm. Am I on the right track here? Is there more going on with how those bearings are mounted? Some detailed pics of it partially disassembled would be awesome! Sizes of the machine screws used would be awesome too (honestly a full hardware parts list would be amazing).

Also, how on earth are you tapping these 3D parts, lol? Just using the machine screw and doing it by hand carefully, or do you have a more professional setup?

Thanks for all the info!

He he, you caught on to one of my secrets! Long story short, I'm using some craft beads called fuse beads (https://www.amazon.c...s/dp/B07MZ674C5), which have a very close inside diameter to fit on the screw (#4-40 screws - which is close to M3 screws in metric), and a very close outside diameter to that of the inside of the ball bearing (5mm). I guess it's not much of a secret now, but I just bought a big container/bag of these from Walmart and look for the ones that fit a bit more snug in the bearings.

In the next couple weeks I'm hoping to make a video on how to assemble the assemblies, which should give you a better idea of all that goes into it.

I also do have a hardware list, which I've been using to calculate out the cost of each of the parts. I'm sure I will share that sometime as well once the design is more finalized.

As far as tapping goes, I did try and tap some with the screws but found the plastic tended to split, so I just ended up using a tap and die to get the threads in the pieces which was more forgiving. I also embedded a couple nuts in the design of the assemblies, which adds extra strength to some of the threaded holes.

#49

Posted 02 July 2019 - 08:41 AM

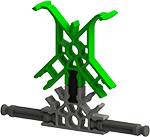

Been a while since I posted anything as I've been slowly working on printing and tweaking parts, but I'm happy to show you a prototype chain dog holder/assembly that works on any middle or rear car! So far they seem to work great, but I'm sending it out to couple people and should get some feedback there!

Edited by JohnnyR24, 02 July 2019 - 08:41 AM.

#50

Posted 08 July 2019 - 03:40 PM

#51

Posted 13 July 2019 - 09:25 PM

Chain dogs per car is going to be awesome. Looks really promising.

#52

Posted 29 July 2019 - 11:07 AM

I first saw this on YT, it really looks amazing. It's not bulky and looks like a normal car with the exception of the actual bearing. I wonder if you could develop this with micro.

#53

Posted 30 July 2019 - 07:12 AM

I first saw this on YT, it really looks amazing. It's not bulky and looks like a normal car with the exception of the actual bearing. I wonder if you could develop this with micro.

Hey thanks!

In regards to the micro knex someone mentioned it earlier in this post and it did get me thinking about designing something for those.

I haven't owned any micro knex and am still a little unfamiliar with them, but started looking at buying some cars and some track the other day.Before that happens though I had a couple questions.

Is these a standard micro car I should buy to get some measurements off of and do these cars have the ability to be linked together to make a train? If I was to develop some assemblies for them I just want to make sure they are a fit for all (or most) micro trains and still have the ability to be linked together, at least that is if the current trains do as well.

#54

Posted 03 August 2019 - 10:45 PM

People use this car for the most part for micro coasters:

https://www.knexuser...nfo_K24153.html

Knex has made them in basically every color you can think of, but they're all the same for the most part.

You use these to connect them, they're little rubber nubs and they can fit into a small cutout hole in the front and back of the car to link them together:

https://www.knexuser...nfo_K24161.html

I personally am not too attached to the micro car design and think they have some large drawbacks, so if that means entirely new cars than that might be pretty cool.

- JohnnyR24 likes this

Every post is a love letter to a forum once full of innovation

#55

Posted 05 August 2019 - 11:23 PM

This is so great, I'm gonna have to get some. Always knew we had to do something about the cheap/small plastic ss wheels.

Vekoma ferris wheel http://www.sscoaster...parachute-jump/

http://youtube.com/nccoaster97 https://www.twitch.tv/shadowmario27

#56

Posted 07 August 2019 - 10:15 PM

These cars look great! They're just flying through all of the elements. I would LOVE if you made one of these for micro cars since I always felt like the wheels were unnecessarily large and cause more speed loss, but it might be a bit hard since the rails are much smaller than SS and you'd pretty much have to design a whole new body for it since the wheel assemblies aren't screwed into the body like with the SS cars. I know absolutely nothing about designing this stuff, but if you could add side wheels as well if you do make a design for micro cars that'd be nice, since they just have wheels above and below the track which I feel causes a lot of speed loss when going through turns.

If you could make this happen I'd literally love you forever. I'll never stop building with micro, but damn does it kill my spirits when I have to build the first element out of the lift hill at 2/3 of its height.

#57

Posted 08 August 2019 - 02:56 PM

I'm waiting for it to cool down and for me to have more time to get working with these new trains.

SSCoasters Administrator

The SSCoasters Forum Rules

#58

Posted 15 August 2019 - 07:44 PM

So I've been talking with Johnny and he's sent me over a full set of these for a train:

Will be starting a project for this early next week so I can give a full review on the performance and usability!

Edit: I don't know why some of these are upside down

Edit 2: Now they're not upside down

Edited by CCreator12, 16 August 2019 - 03:01 PM.

Every post is a love letter to a forum once full of innovation

#59

Posted 16 August 2019 - 02:47 PM

These are so pretty.

#60

Posted 24 September 2019 - 06:56 PM

So I built a ride with these but I don't have much video of it and due to the constraints of time and space I don't know if I really want to post what I ended up with.

I will say a few non scientific observations I made purely based off of feel:

1. An unweighted 5 car ball bearing train felt similar to a 5 car heavily weighted and well lubed train in terms of speed loss.

2. I think these might get gummed up pretty easily due to the exposed wheels and bearings so I think I lost some performance during the week I used them, so cleaning them will be important for longevity.

3. Even the 'dirty' bearings would more than double the spin time by flicking the wheel as opposed to the stock, lubed trains.

So the way I see it having the bearings opens you up to two possibilities:

1. Running an unweighted train and saving on supports/parts (still likely performs better than stock SS)

2. Running a weighted train and be able to do things that were impossible just 6 months ago using stock SS trains.

In my case I chose option 1 so I didn't really test weighted 5 car trains on my ride because I could get away with a lot less supports, but these things are really the future of our hobby and I would recommend getting your hands on them.

Every post is a love letter to a forum once full of innovation